Introduction: The Misconception of “Instant Protection”

One of the key reasons why people buy luxury leather shoes is due to their comfort, which includes breathability. The application of waterproof sprays, at core, converts these shoes into plastic, and the true luxury of footwear is lost. While it seems like the shoe is instantly protected, waterproofing sprays directly impact the aesthetics of the shoes.

Offering waterproof spray as a luxury footwear brand is counterproductive for both the structural integrity and intricate artistry of the brand and the long-term trust of the consumer. The right way is to recommend alternate techniques that not only improve the luxury shoe aesthetics but also make them last longer. By promoting short term convenience brands endorse a product that suffocates their products that customers pay for and enjoy.

For heritage-focused collections—especially from a dedicated oxford shoes manufacturer—preserving leather’s breathability isn’t optional; it’s essential to the brand promise.

This article will explain why waterproofing sprays are bad for luxury shoes, explaining their short-term and long-term impacts on shoe quality. Instead, it will provide alternate, well-developed, tried and tested techniques for luxury shoes. It will include care and design techniques for shoe build to make them waterproof without the negative effects. Let’s begin with the guide!

How Sprays Degrade Premium Features of Luxury Footwear

The waterproof sprays are great for shoes that are already non-porous and feature a surface that is already made with synthetic fibers. For shoes made with natural materials like leather, waterproof sprays can have a negative impact on the very features that set them apart from low-end shoes.

The Porosity Problem

High-grade smooth leather, like calfskin, works similarly to human skin. The porous structure allows moisture to pass through while providing flexibility. Using waterproofing sprays creates the following problems:

● Silicon Blockage

The waterproof sprays are based on silicon material. Their application makes the shoe waterproof. The silicon molecules expand inside the calfskin pores and block them to form a seal that eliminates breathability. Moreover, the blockage of pores means that it cannot take in essential oils from conditioners, resulting in dryness and microscopic cracks.

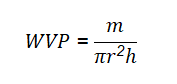

● Water Vapor Permeability

The water vapor permeability (WVP) is the measure of leathers ability to breathe. It is calculated using:

A higher WVP means that the leather is breathable. Typically, the calfskin 8 to over 10 mg/cm².hr. In comparison, the application of waterproofing sprays drops it to 0.5 mg/cm².hr. The lack of exchange leads to break down of fiber, reducing the shoes by 50% in humid conditions.

● Salt Trap and Internal Abrasion

Human sweat contains salts that, in a porous material, reach the surface and are easily removed using conditioners and polishes. The waterproof sprays trap salts inside, leading to stiffness of materials and permanent discoloration. Microscopic studies show that the spray residue converts pores to dust traps. These dust particles act as sandpaper against internal fibers every time the wearer takes a step.

The Aesthetic Sabotage

Visuals are created when the light reflects back to our eyes from an object. Sprays alter the optical property of the leather by covering the grain ruins the beauty of premium calfskin.

● Plastic Mask

The application of spray creates a layer of thin synthetic sheen that toys with the natural character of the luxury leather shoe. The grain structure of leather is masked, which gives each shoe its unique identity. Moreover, the application causes the surface refractive index to change, leading to the loss of the three-dimensional look of leather.

● UV Degradation and Peeling

The spray sits on top while the natural oils are soaked into the leather. With time, the UV exposure leads to the degradation of the chemical, resulting in yellowing and peeling. The peeling can create a flake-like appearance, which hinders the elegant aging process of leather.

● Natural Feel

The spray leaves the surface of the shoe to feel slick or wax-like, diminishing the true leather experience of premium craftsmanship. Moreover, developing patina that adds value to the shoe is halted.

Alternates to Waterproofing Sprays for Luxury Footwear Brands

For a luxury brand, it is best suitable to offer features that make sure that the luxury shoe is engineered and pre-cared in a manner that there is no need for waterproofing sprays. Moreover, luxury brands can offer tips to their customers to keep the natural features of the shoe through care routines. Here are the foundation pillars for a truly luxury brand:

Pillar 1: Structural Integrity through Goodyear Welt (GYW)

Instead of showcasing waterproofing spray, opt for constructing shoes that feature a Goodyear welt (GYW) like Hengxin. The design makes the shoe mechanically waterproof. The multi-layer approach that utilizes a welt to attach the upper to the insole creates a robust physical barrier. It acts as a barrier that repels water at the sole junction. The design leaves a cavity that is filled with natural cork paste. Overall, the shoe creates a balance of moisture, ensuring M=0:

M = Absorption Rate -Evaporation Rate

Pillar 2: Hand-Finished Artistry (Patina)

Premium brands add a human factor to their production, which creates character and adds uniqueness to each and every product. Hengxin is one of the leaders in hand-applied Patina. The process that takes years to develop, experts create them using their 14 years of experience. The process is unique for a manufacturer in China.

There are 7-10 steps where the pigment penetrates 0.2-0.5mm into the hide. It fills the fibers with stain protection while allowing them to be flexible. The unique process applied to Hengxin luxury footwear creates pieces of art that perfectly complement their bespoke three-piece suit, giving it the suit shop edge. A waterproofing spray, on the other hand, would hinder the pigmentation.

Pillar 3: The Natural Maintenance Protocol

It’s vital to ensure that the customer is well-aware of the maintenance protocol to ensure that their luxury shoes remain as new. Since the high-grade calfskin is an organic, porous material, maintenance must maintain the Refractive Index (1.3) and the Vapor Permeability of the leather. The customer needs to perform:

- Cleaning: removing grit using a horsehair brush is vital. The grit can act as sandpaper and create micro-tears that allow water to seep in.

- Nourishing: Just like any human skin, hydration is key. Use creams with natural oils like Mink, Macadamia, or Shea. These penetrate 0.2mm deep into the leather. The process helps the leather retain 6–8% oil content required to prevent cracking.

- Protecting: Using hardwaxes like the Carnauba and Beeswax creates a hydrophobic barrier but allows vapor permeability. Moreover, applying wax directly to the welt stitches on a luxury footwear product plugs the threadholes, reinforcing the mechanical barrier.

Pillar 4: Pro-Tips for Long-Term Integrity

For professional wearers who care for their luxury shoes, following these tips can prolong the leather’s integrity and aesthetics:

- 24-Hr Rule: Never wear the same shoe two days in a row. Allow the leather to evaporate the moisture absorbed from the feet.

- Cedar Shoe Trees: Using cedar draws out moisture from the cork filling as it is hygroscopic.

- Avoid Heat: Do not heat your shoes to dry them out. Heating leads to the breakage of proteins, leading to 25% increase in brittleness.

Solving the B2B Manufacturer Pain Points

Finding the perfect balance for artistry and business scalability is a challenge for any luxury brand. Devising a solution to the problem helps emerging brands deliver luxurious products without compromise. It’s important for manufacturers to shift focus from mass production to tailor-made solutions that conform to artisanal standards. Hengxin provides B2B solutions and puts energy into quality control and flexibility in the supply chain to help brands grow.

Quality Control (QC) Over Quantity

The best protector of the shoe isn’t a waterproofing spray for footwear. It’s the rigorous process of evaluating raw material before use. Hengxin has strict QC in sourcing and production. Here are three aspects to focus on at the factory level to ensure that the end-user doesn’t feel the need to spray:

- Uniform Thickness: Ensuring consistent density across the entire hide is key. Typically, the thickness is around 1.2-1.6mm.

- Standardized Lipid Balance: Using advanced technology like spectrometers to measure oil uniformity that can detect minor variances as low as 0.5%. It creates a lipid balance of 8–12%.

- Porosity Calibration: Using visual and tactile checks ensures the leather is breathable.

Flexible Supply Chain for Growing Brands

Strategic decision-making is key to ensuring that the brand maintains its artisanal image while catering to the market demand. Here are ways brands can utilize offers from Hengxin:

- Boutique-Friendly MOQs: Hengxin offers low Minimum Order Quantities of around 50 to 100 pairs. With such low MOQs, brands can test different designs and observe which ones are the hot sellers. It helps them manage capital risk. Allow brands to test new designs without massive capital risk.

- Rapid Iteration: To reduce lead times, Hengxin uses modular components of shoes to ensure lead times between 4 and 6 weeks. It allows rapid adjustments to the market trends.

| Metric | Mass Production | Hengxin Artisanal B2B |

| MOQ | 500+ pairs | 50–100 pairs |

| QC Focus | Visual Surface Only | Spectrometer Oil/Thickness Analysis |

| Return Rates | 10–15% (due to inconsistency) | < 2% (due to rigorous QC) |

| Lead Times | 3–6 months | 4–6 weeks |

Conclusion: Investing in Quality Over Maintenance

For luxury brands seeking a reliable men dress shoes supplier, the answer lies not in chemical sprays—but in superior construction, material integrity, and artisanal finishing.

Premium shoes do not require waterproofing spray. They offer high-end engineering techniques and pass shoes through intricate processes that result in waterproof capability while maintaining the luxury feel. Using Goodyear Welt (GYW) and hand-finished patina during shoe production. Sourcing premium-grade material and providing end-users with pro-tips to maintain shoe health leads to longevity of luxury footwear.

Partnering with a brand that understands these nuances is the first step to elevating your brand from standard to luxury. Hengxin provides artisanal B2B services for brands aiming for the premium footwear market segment. They use high-end technology and years of expertise to solve manufacturer pain points. By prioritizing structural integrity over chemical coatings, Hangxin ensures its partners get the highest-grade calfskin. Visit Hengxin’s website https://www.dressshoefactory.com/ to explore all their processes and premium footwear collection for your B2B business.

FAQ

Q: Does smooth leather need any waterproofing at all?

A premium grade smooth leather has natural resistance due to its grains and oils. These are sufficient for light rain without any treatments. For more water exposure, rely on waxes or creams that enhance resistance to water without clogging the pores or degrading leather.

Q: If I shouldn’t use spray, how should my customers maintain their shoes?

Provide guidelines to follow three things: clean, nourish, and protect. These are done using regular brushing to remove sand grains, using creams with natural oil, and applying hardwaxes that ensure porosity while providing waterproofing.

Q: How does Goodyear welted construction help in wet weather compared to glued shoes?

The Goodyear welted construction attaches the upper to the sole using a welt. The presence of welt forms a waterproof barrier that physically stops the water from seeping into the shoe. In comparison, glues lose their adhesiveness and dissolve when wet.

Q: Will waterproofing spray ruin a hand-painted Patina finish?

The outlook of a hand-painted patina depends on how the light reflects off the surface. Using a waterproofing spray causes the refractive index to change. It creates a plastic-like look, traps salt, which results in haze, white residue, and fiber stiffness.

Q: How do you ensure quality control across a large batch of handmade shoes?

We use spectrometer-based analysis to standardize oil content (8–12%) and thickness (1.2–1.6mm). Multi-stage artisan inspections and porosity calibration ensure consistent breathability and prevent defects before shipping.