Introduction

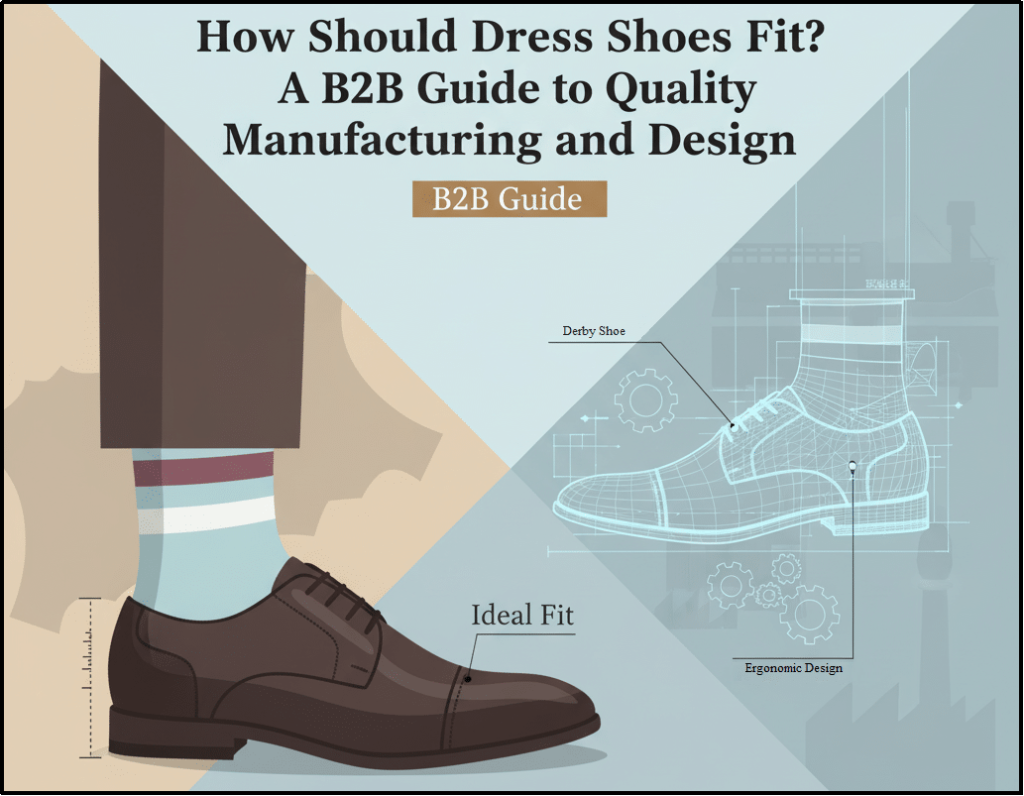

Have you ever tried on a dress shoe that felt too tight, only to be told it will get better with time? While that sentiment has a grain of truth, a truly discerning buyer still needs a proper understanding of shoe fit to find the right manufacturing partner.

A poorly fitting shoe can compromise even the most stylish design, and people of style know it. A tight shoe can stretch and mold to a foot, but an overly tight shoe can stretch beyond its shape, causing cracking in leather and distortion in appearance.

A true gentleman knows that a polished appearance comes with a perfect fit. Dress shoe manufacturers that understand this stick to the science behind proper fitting. They utilize the most mature and time-tested techniques to strike a balance between ergonomics and aesthetics. Choosing the right material, production process, and ensuring strict quality control can lead to premium dress shoes like Hengxin.

This article is a guideline for B2B partners in the shoe industry, showing them how attention to fit and manufacturing quality can set their products apart from competitors.

The Science of Proper Fit in Dress Shoes

Making a perfect fit dress shoe that works for the masses requires a thoughtful design process and the use of science. It is a combination of manufacturing techniques and the utilization of feedback from the millions of consumers around the world. From the first feel to the long term, the techniques will ensure a fit that defines quality in men’s footwear, particularly dress shoes.

❖ First Wear Feel

While consumers expect a break-in period with new dress shoes, there’s a fine line between a snug fit and discomfort. For B2B stakeholders and manufacturers, addressing this precise gap is a crucial marker of quality. This is the gap that custom men dress shoes are designed to bridge. By focusing on superior, personalized fit from the outset, they deliver immediate comfort that surpasses conventional expectations, transforming the first-wear experience. It’s important to consider:

- The full-grain or calfskin leather should break in after several wears to suit the user.

- Preconditioned shoes are easier to break in.

- The first-time wear should feel snug for its size, but not overly so.

- Use true-to-size sizing mention (US, EU, and UK) standards for the shoe.

❖ Room in the Toe Box

Having the right amount of room in the toe box is key to ensuring a good fit. Too much and too little can cause problems for the wearer. Too little space can cause discomfort and deformities like bunions, hammer toes, and blisters. Whereas, too much space can lead to instability, foot sliding, and potential blisters or lack of support. Therefore, as manufacturers, it’s vital to ensure the right space based on design. Stick to the following to ensure the right fit:

- The toe box should have about ½ inch to ¾ inch of space between the longest toe (often the second or third toe) and the front of the shoe.

- Use full-grain or calfskin leather for moldability to the user’s feet.

- Ensure a breathable inner lining.

- The design should not squeeze the toes together but allow natural spacing of toes.

❖ Slip Prevention

Leather outsoles can be slippery, which can affect user comfort and reduce control. Having a slip prevention design aspect proves to be a great selling point for users who work in places that expose them to wet or slippery surfaces. Here are some ways manufacturers can incorporate slip prevention in their design:

- Use Vibram or Dainite rubber soles, known for their durability.

- Incorporate ridged grooves, herringbone, or diamond texture in the outsole

- Use a rubber “top piece” on the heel to maintain elegance

- Apply thin rubber pads “Topy Soles” for discreet slip resistance

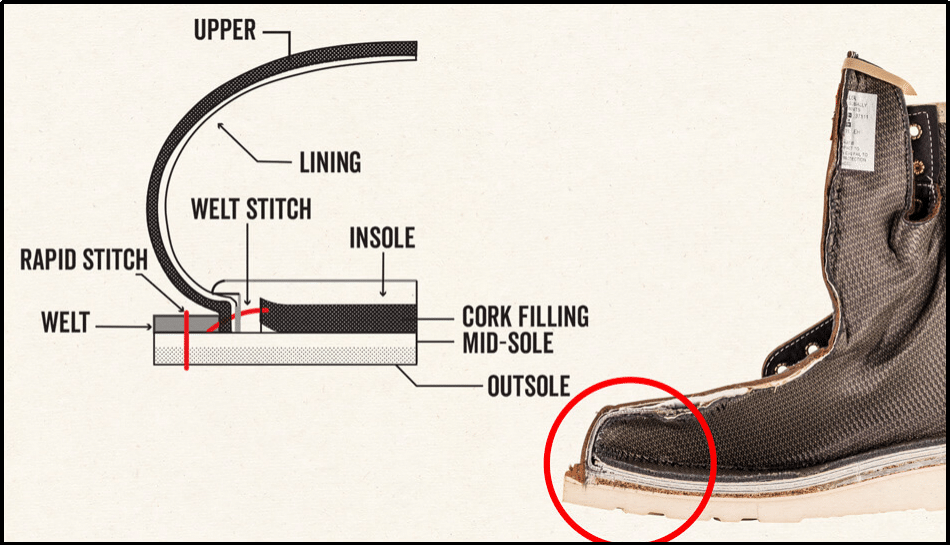

❖ Cork Filling and Shank Support

Goodyear-welted shoes are the highest quality shoes that manufacturers can offer. These are named after the machine that stitches them into shape. However, the design inherently leaves behind a space underneath the shoes that needs to be filled before the outsole is stitched. Filling the area with cork and adding a shank support can enhance the customizability of the shoe. The shoe can gradually adjust to the user as the cork compresses, providing a personalized, snug fit that becomes more comfortable with each wear. Shank support made from wood, plastic, or metal ensures that the shoes do not end too much from the middle.

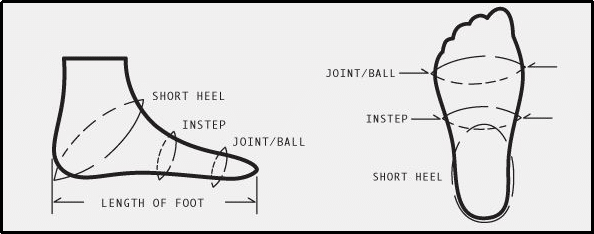

❖ Structural Elements That Influence Fit

- Arch: Using cork or memory foam in the footbed and midsole provides comfort and support for the feet. However, manufacturers should consider the material to be ergonomic without feeling too rigid or uncomfortable on the first wear.

- Width: Offer multiple width options for the consumer, as shoe size does not address the width of the feet. It allows customers to find the most comfortable fit. The toe box and midfoot should be constructed to provide adequate space without being too wide, which could cause instability. The shank support and the arch should provide structure, ensuring the shoe fits securely across the entire width of the foot.

- Instep Comfort: The area that wraps around the arch should apply gentle pressure on the area. Consider material that can soften and mold over time.

Craftsmanship That Guarantees Comfort and Longevity

Every manufacturer will offer a unique aspect as their area of expertise. It could be the use of premium material, unique designs, or meticulous hand-finishing techniques. Here are three craftsmanship that ensure longevity with utmost comfort for users:

1. Goodyear Welt Construction (Hengxin’s Core Strength)

Amongst all the dress shoe manufacturing techniques, the Goodyear Welt construction of dress shoes takes the crown. It offers exceptional adaptability to the wearer’s foot over time. The technique, which originated in 1871, has endured for more than a century. It is associated with high-quality footwear owing to the machine-based process that attaches the sole to the upper via a leather welt.

Alongside excellent reliability, which initially drove sales, the shift in consumers’ focus came towards their comfort. The filling of cork between the insole and outsole compresses gradually, adapting to the wearer’s unique foot shape. Goodyear Welt creates a separate stitching layer between the upper and sole. The upper and outsole are not directly sewn together. Only the welt is stitched to the sole. It allows the sole to be removed and replaced multiple times. Premium and high-end shoe manufacturers like Hengxin boast Goodyear welt as their core strength.

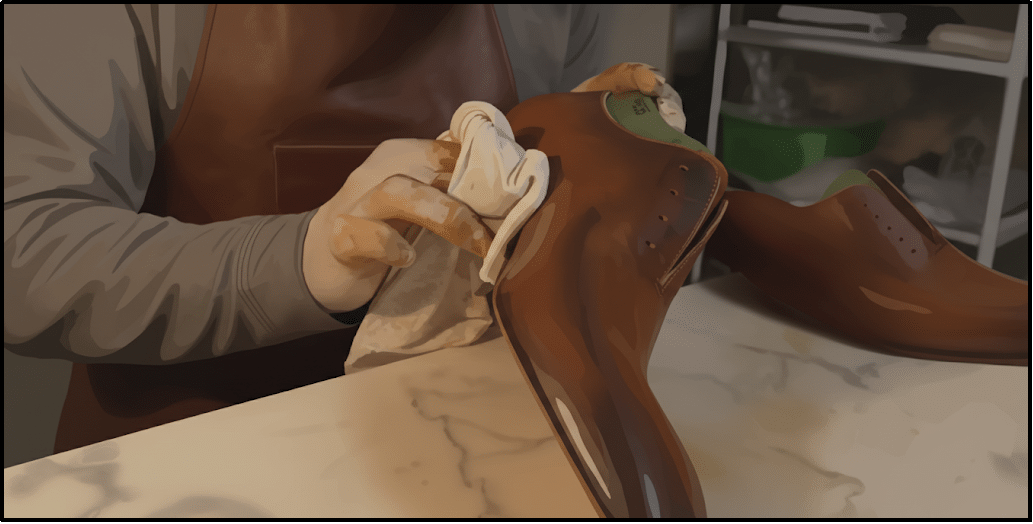

2. Hand-Patina Finishing

Handmade items have always been a luxury. In dress shoes, aesthetic additions like hand-patina add value. It involves introducing an aged look to the shoe with layered coloring. It adds character to the shoe, and Hengxin is among the few Chinese manufacturers that master artisanal patina work. The technique requires a meticulous hand, making each pair a distinct work of art.

For B2B partners, shoes with hand-patina finishing indicated commitment to craftsmanship and luxury, targeting the premium market segment.

3. Balancing Aesthetics with Ergonomics

The toe shape for the Oxford, Derby, and Monk is different. The change in shape can also affect the ergonomics. It’s vital for manufacturers to consider the shape differences and how they cater to toe box room, first wear, slip prevention, and other structural elements.

- Oxford: Tapered and sleek, giving a formal appearance. Requires precise sizing to ensure the structured fit is comfortable.

- Derby: Rounder and slightly wider toe box, allowing more flexibility, ideal for semi-formal or everyday wear.

- Monk Strap: Snug front with straps; toe shape can emphasize style while still supporting comfort.

How B2B Partners Can Leverage “Fit” in Their Shoe Collections

Meeting Market Expectations

Matching the market demand is a key aspect to keep the products relevant and market competitive. Catering to regional style preferences can also result in improved sales. B2B partners can leverage “fit” nuances, such as the Romier toe box, which is favored by American consumers, and a slightly narrower, more tapered toe box preferred by European consumers, which can lead to a better market response. Moreover, offering half-sizes and width options can result in higher customer satisfaction and retention.

Communicating Quality to End Customers

As B2B partners, adding aspects that are well respected amongst the dress shoe community can signal quality. Goodyear welt construction and hand-applied patina finishes act as tangible markers of quality. For private-label brands, highlighting such construction in marketing materials differentiates products in a crowded dress shoe segment, positioning the collection as both elegant and reliable.

Why Manufacturing Partnership Matters

Having experience is key to producing a high-quality product. Technical expertise is required for the last design, arch support, shank placement, and cork filling—all elements that determine the final comfort and performance of the shoe. Hengxin’s approach ensures that B2B clients receive footwear collections aligned with both style expectations and ergonomic standards.

Having an experienced partner like Hengxin, which has extensive market feedback, can produce dress shoes that result in enhanced end-user satisfaction and trust.

Conclusion: Fit + Craft = Long-Term Brand Value

A shoe that fits comfortably for a wide range of end-users reflects the manufacturer’s attention to detail and craftsmanship. For B2B businesses, collaborating with manufacturers that value fit can result in greater customer satisfaction and enhance brand image. Incorporating aspects such as Goodyear welt construction and hand-patina combines ergonomics with aesthetics.

Hengxin stands out in China with unmatched Goodyear welt construction and hand-patina finishing, delivering excellence that brands can confidently present to their customers. Visit their website to witness pristine and precise dress shoe craftsmanship.

FAQ

Q. How much room should you have in a shoe for comfort?

There should be around ½ inch to ¾ inch (roughly a thumb’s width) of space between the longest toe and the front of the shoe. That’s roughly the width of a thumb. Moreover, quality shoes gradually adjust to foot size with modal full-grain ro calfskin leather.

Q. Should new leather shoes feel tight at first?

Yes, in high-quality GoodYear Welt shoes, there is a break-in period that can be around several wears. It is the hallmark of premium shoes that allows the leather to gradually mold to the wearer’s foot.

Q. What role does the shoe-last play in achieving the right fit?

The shoe-last is the mold that is a replica of your shoe shape. A precisely crafted shoe-last can result in a better overall shape, improved arch support, and more accurate toe box dimensions, particularly in GoodYear Welt shoes.

Q. How can B2B brands use fit as a selling point in premium footwear?

The key selling point of premium footwear is its durability and longevity. The shoe should be repairable and a perfect fit for the end-user. B2B brands realize that a fit is a critical factor in perceived quality. Features like cork-filled insoles in Goodyear-welted construction are considered premium..

Q. Why does patina finishing matter for both fit perception and brand identity?

Patina finishing adds character to the dress shoe. It also exhibits attention to detail and customization of the product. Every patina finish shoe is unique in its looks as they are all hand-done.