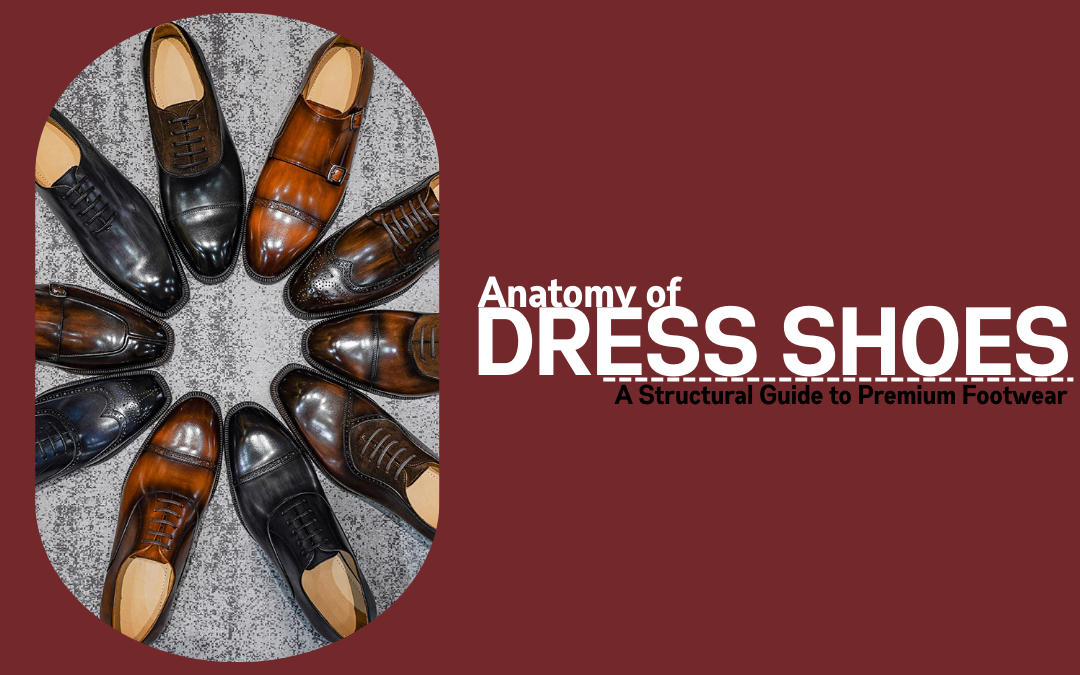

Footwear, though seemingly simple, contains intricate details that influence comfort, aesthetics, and durability. Premium shoes not only offer a refined outward appearance but also rely on a strong internal structure, with hidden components designed to help them withstand the test of time. For example, a pair of hand-welted dress shoes can take a craftsman 40-60 hours to complete, a testament to the delicate and precise process of making dress shoes.

Knowing the anatomy of dress shoes helps appreciate and recognize true craftsmanship. A quality shoe is a system of engineered parts working together to provide both confidence and elegance. At Hengxin, every Goodyear-welted shoe is built with meticulous attention to structural detail, resulting in footwear that appeals to enthusiasts who value premium construction and timeless style. Let’s now explore the foundation of a dress shoe, one component at a time.

The Foundation: Understanding the Sole Unit

Humans have been protecting their feet for thousands of years, with the oldest known footwear dating back 10,000 years. The foundation of every footwear, from sandals to modern dress shoes, has been meticulously designed to serve the purpose of traction, durability, and comfort. To understand the foundation, we break it into three parts: outsole, midsole, and heel.

Outsole

It is the part at the very bottom of the dress shoes that touches the ground. The purpose is to provide grip and protection for the foot.

●Material

- Leather: In premium footwear use of leather on the outsole is common. They offer breathability and a distinct walking sound.

- Rubber: The use of rubber as the outsole results in better grip. It is good for wet surfaces and water resistance. Users can opt for Vibram or Dainite soles depending on their preference.

- Combination: For users who prefer a better grip on their leather shoes, a rubber “top piece” over the heel can provide additional grip.

- Halfsole:A half-sole or topy sole can also improve grip through he use of a rubber sheet that covers the contact area of the leather sole.

● Attachment Method

- Stitching: It is the most premium method of attachment as it requires skilled craftsmanship. The stitching method and type can result in different kinds of dress shoes, for example, Goodyear Welt and Blake/Rapid Stitch.

- Cemented: The upper is glued to the outsole, resulting in a lightweight shoe with no break-in time. However, it’s less durable and may be an indicator of other substandard material.

●Stitch Types

- Open Channel Stitching – Sole stitching is visible.

- Closed Channel Stitching – Sole leather is cut and folded back over the stitching for a cleaner look.

Midsole

The material that sits between the insole (the part that your foot directly comes in contact with inside the shoe) and the outsole is called the midsole.

●Function

It is the key component that ensures that the dress shoe is more comfortable to wear. Moreover, it offers shock absorption and support for the feet.

●Material

- Cork: The use of cork is highly valued in premium dress shoes. As time passes, the material deforms to your foot shape, offering a personalized footbed.

- Leather: Some may prefer a firmer leather feel as a midsole.

Welt

The use of welt is an exquisite feature of premium Goodyear-welted shoes. It sits around the perimeter of the shoe.

●Function

The welt forms a bond between the upper and outsole while acting as a barrier against water and dust ingress. The stitching goes through the welt into the outsole, and another set of stitches goes through the upper and insole.

●Uses

Welts are used in Hand-welted, Goodyear-welted, or Norvegese/Norwegian welt, but the process is distinct.

Heel

The heel is the raised portion at the back of a premium dress shoe. It is often made from stacked layers of leather. The very bottom layer that touches the ground is called the top piece (can be leather or rubber).

●Function

The heel provides elevation and balance. It enhances durability in areas where the shoe wears down the fastest.

●Material

Stacking multiple layers of leather will result in a heel. The last layer is called the top lift. It protects the shoes from wear and tear. A skilled cobbler can remove and replace the toplift conveniently in shoes that feature them. It may even use plastics to enhance the durability of the heel.

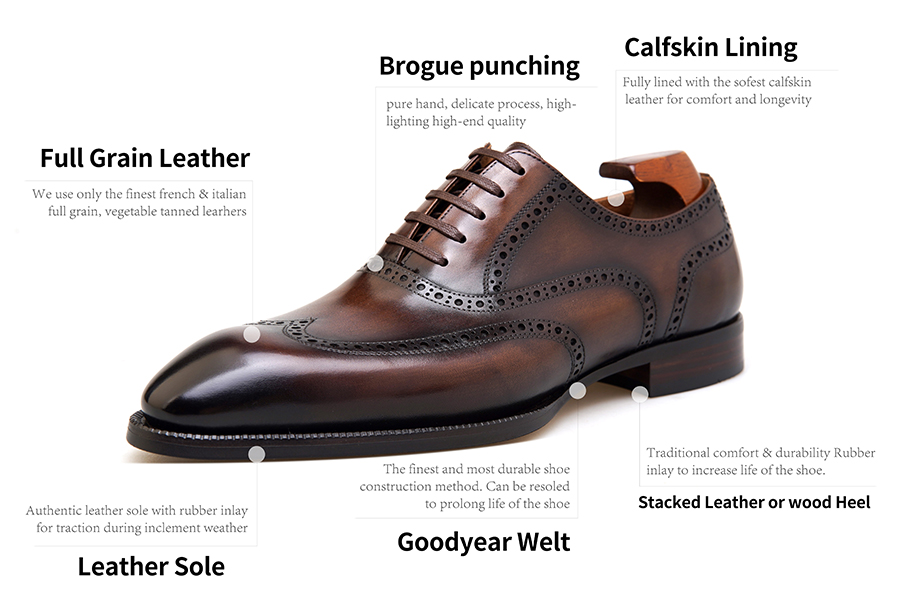

Upper: Structure Meets Style

The upper is the most visible and style-defining part of a dress shoe. It not only determines the shoe’s aesthetic appeal but also plays a key role in comfort and durability. Premium uppers require meticulous craftsmanship, from leather selection to finishing. For example, producing top-grade Cordovan – a horsehide leather prized for its smooth, non-creasing, glass-like surface – can take up to six months of skilled tanning and finishing.

To better understand its design and function, the upper can be divided into three main sections:

Vamp and Toe Box

- Toe Cap: The frontmost panel of the upper, often crafted as a separate piece of leather and stitched across its edge. It adds style definition and reinforcement to the toe area.

- Vamp: The section directly behind the toe cap, covering the top of the foot. As the area where most foot movement occurs, the vamp must balance flexibility with strength to maintain comfort and shape.

- Toe Box: The internal structure beneath the toe cap and vamp that shapes and protects the toes, offering either firm support or a softer feel depending on design.

Quarters and Eyelets

- Eyelets: The reinforced holes through which laces are threaded. A typical dress shoe may have around five eyelets per side, but this varies by style. The placement of the eyelet affects fit and tension.

- Quarters: The side and rear panels of the upper extending from the vamp to the back of the shoe. Quarters can be separate pieces or cut as one with the vamp, joining at the back seam over the heel.

The location of the eyelets and quarter design plays a vital role in determining whether the shoe type is Oxford or Derby. An open lacing system (Derby) has separate flaps that are open freely. In comparison, the closed lacing system (Oxford) features lacing attached under the vamp, giving it a closed and formal feel.

Backstay and Collar

- Backstay: A vertical strip of leather reinforcing the seam where the two quarters meet at the back. This element adds structure and helps the shoe retain its shape over time.

- Collar: The top edge of the quarters forming the shoe’s opening. Dress shoes typically feature a sleek, unpadded collar for a refined silhouette, while casual designs may incorporate padding for added comfort.

Some shoes may even feature a heel cap, which can also be called the backstay. Collectively, the backstay and collar help support the ankle and ensure that the shape remains intact. Some may even have padding to improve comfort and fitting.

Interior: What’s Beneath the Surface

Underneath the premium leather material that exhibits brogueing to add character to the shoe, there are layers of material that provide comfort and boost the user’s confidence. Everything from the stitching technique to the selection of material can impact how you move around with the shoe and the time the shoe takes to break in to your feet’ dimensions.

Insole and Footbed

- The Insole: The layer inside the shoe where your foot rests. In Goodyear welted shoes, the insole is stitched together with the welt and upper. The insole can be integrated or removable.

- Footbed: Typically refers to the cushioned top surface of the insole that contacts the foot, sometimes molded or contoured for comfort. As mentioned earlier, in premium shoes, cork filling beneath the insole (in Goodyear welted construction) molds to the wearer’s foot shape over time for a personalized fit.

Brands like Hengxin combine modern engineering with traditional craftsmanship to improve shoes longevity. Traditional Goodyear Welting stitches a welt to the canvas rib (a cloth strip cemented to the bottom of the leather insole). In 360° channeling by Hengxin, the leather insole itself is directly channeled, meaning a groove is cut directly into the leather. The welt is then stitched directly to this carved channel. The process is more labor-intensive but produces a stronger and compact connection.

Lining

The lining in typical Goodyear welted dress shoes is the part that completely covers the foot from the inside. It protects the feet from rubbing against stitches and uneven surfaces. The selection of lining material is key as it protects the outer layer from sweat and ensures that the premium dress shoe is durable, soft, and resistant to shrinkage and cracking. It can be in a full or partial lining configuration, depending on the price tag of the shoe.

Hidden Support Elements

- Shank: Embedded between the insole and outsole in the arch area. Provides stability, supports weight distribution, and helps maintain the shoe’s shape.

- Sole Filler: The space between the insole and outsole (created by welt construction) is filled with cork for added comfort and shape retention; cheaper shoes may use foam.

- Backstay: A vertical reinforcement strip at the rear seam of the quarters that strengthens the heel area.

- Heel Counter: It is a stiff, internal shoe component that cups the heel to provide support and help maintain the shoe’s shape.

Buying Tips for Dress Shoes

- Wavy Outsole: Look for a wavy outsole at the edges. It can be an indication of substandard workmanship, which can cause water and dust to eventually result in damage.

- Cut Marks: Avoid shoes with cut marks and uneven stitching, as they compromise the shoe’s water resistance.

- Sole Layers: For the sole heel, check that layers are neatly stacked and securely attached. For the upper heel area, look for smooth stitching and even leather quality.

- Heal Height vs. Health: An optimal heel pitch for a men’s dress shoe is 1 to 1.25 inches. Heel heights over 3.15 inches can cause significant strain on the ankles and arches.

- Lining Quality: The lining material should be neatly stitched with no loose edges. It should be comfortable even without the socks on.

Conclusion: Anatomy Reflects Craftsmanship

Every shoe that a skilled craftsman produces has a purpose. Everything from the structure, selection of material, welting technique, and design comes together to form a perfect dress shoe tailored for an individual. Learning about the show anatomy allows buyers to access the quality of the show and appreciate the minor details that craftsmen utilize to create a truly timeless piece of footwear.

At Hengxin, we truly believe that constructional excellence results in the perfect blend of form and function. It is this deep-rooted philosophy that drives our commitment to creating high-end footwear. We utilize full-grain leathers in our uppers, build a strong foundation with our Goodyear welted construction, and utilize our signature 360° channeled insole for a superior, personalized fit. Visit our website to explore a meticulously designed collection of shoes that speak to premium footwear!

FAQ

- What is the purpose of a shoe welt?

The shoe welt is a component that runs around the perimeter of the shoe. It holds together the upper and outsole with the help of stitching, acting as a staple component of Goodyear-welted shoes. Moreover, it acts as a barrier against water and dust.

- What materials are used in the soles of high-end shoes?

Typically, a premium-grade dress shoe will feature a leather sole. But the sole material depends on the application. Some may feature a Vibram or Dainite material sole designed for wet conditions.

- What’s the difference between Oxford and Derby construction?

The Oxford construction is more formal and features a closed lacing system. The eyelet flaps are attached beneath the vamp. In comparison, Derby has flaps over the vamp (open lacing system), making it slightly versatile and a less formal option.

- How do insoles and linings impact the feel of a shoe?

Insoles can be leather or cork. Whereas the lining can be premium leather or synthetic. High-end insoles like cork can conform to foot shape and offer shock absorption. Similarly, premium leather linings can make shoes comfortable even without socks. Moreover, it also determines breathability and cushioning.

- What is the role of the steel shank in dress shoes?

The steel shank adds rigidity to the dress shoes. It prevents the shoe from flexing excessively. Moreover, it provides stability to the shoe and helps maintain the overall structure and shape over time.