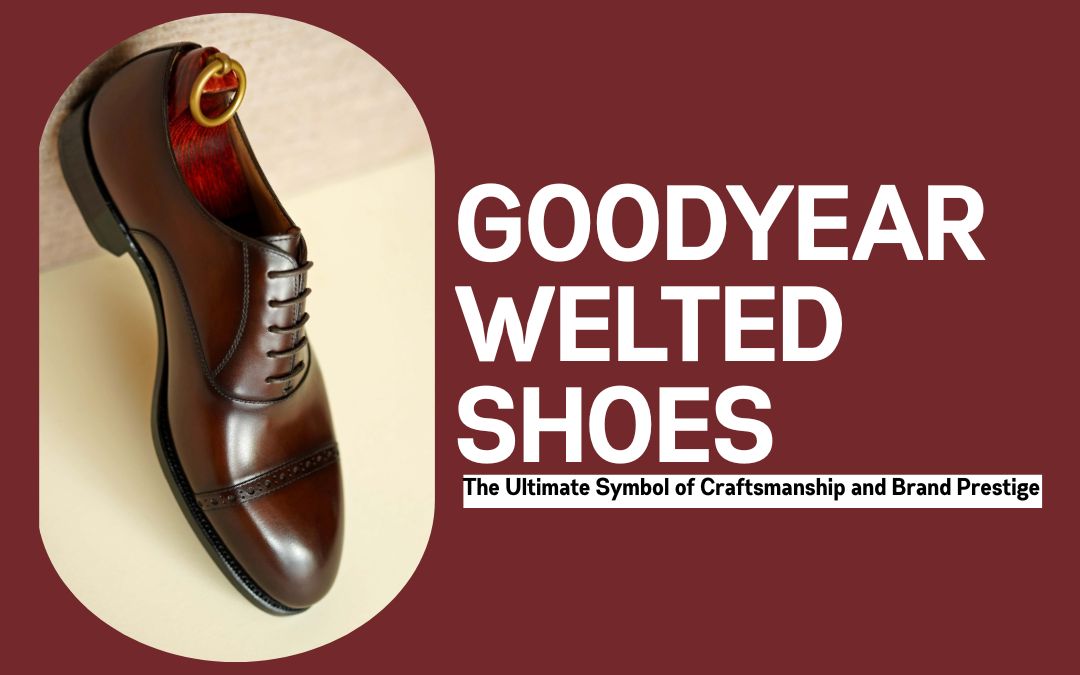

Introduction: The Art and Integrity Behind Goodyear Welted Construction

If you’ve ever slipped on a pair of great dress shoes and thought, “Whoa—that feels solid, supportive, and somehow elegant,” there’s a good chance you were standing in Goodyear welted magic. These are the gold standard in men’s footwear—durable, comfortable, and timeless—precisely because of how they’re built and how they age with you. The longer you wear them, the more they feel like yours. That bond is addictive. You’ll see.

And for footwear brands? This construction isn’t just a feature; it’s a statement. Mastering Goodyear welting signals you can produce products that don’t just look premium on day one—they keep earning their keep years later. When you’re positioning a line for serious customers, that’s the kind of credibility you want stitched right into the product.

A quick note about Hengxin, the manufacturer behind Dress Shoe Factory: founded in 2011, the company has dedicated over 14 years to perfecting Goodyear-welted footwear and advanced patina finishes, supporting private‑label partners with both OEM and ODM capabilities. They emphasize traditional craft—down to channeling the insole for a direct welt stitch—while scaling modern production for global brands. Running late, the idea still stuck: few factories can pull off true Goodyear welting consistently at scale, and Hengxin is one of them.

Understanding the Goodyear Welted Construction Process

What Is Goodyear Welt Construction?

At its core, a Goodyear welt is a strip—traditionally leather—sewn around the perimeter of the shoe, attaching to both the upper and the insole’s rib. The outsole is later stitched to this welt, not directly to the upper. That small technical choice unlocks big benefits: durable structure, water resistance, and easy repairs. Historically, the process was systematized in the 19th century with machinery improved under Charles Goodyear Jr.’s name—part of the mechanization wave that allowed welted shoes to be produced consistently and resoled over time.

Why it stands apart from other methods:

- Compared to cemented construction (where the sole is glued on), Goodyear welted shoes are designed to be rebuilt.

- Compared to Blake-stitched shoes (inside stitch running through insole and outsole), the Goodyear welt keeps the outsole attachment away from the foot, improving weather resistance and serviceability.

The Layered Structure of Excellence

Think of a Goodyear-welted shoe like a well-built house—foundation, frame, insulation, roof—each layer doing a job.

- Insole & welt connection

The welt acts like a bridge, locking the upper to the insole’s rib (also called gemming in many factory methods) using a specialized stitch. Some makers carve a holdfast (a channel) directly into a thicker insole instead of using gemming—more on that in a moment. - Cork filling for comfort

The cavity beneath the insole gets filled with cork. Over weeks of wear, it compresses and molds to your footprint. That’s why a good welted shoe goes from “nice” to “made-for-me.” - Outsole stitching & finishing

The outsole is stitched to the welt—again, not to the upper—so a cobbler can remove a worn sole without disturbing the shoe’s structure. Crazy, right?

A simple stack view you can picture:

- Upper

- Insole with rib/holdfast

- Welt (stitched to upper + insole)

- Cork fill + shank support

- Midsole (optional)

- Outsole (stitched to the welt)

Why this matters for manufacturers and brands:

- Long-term durability earns loyalty and referrals.

- Premium positioning: Goodyear-welted footwear stands shoulder-to-shoulder with heritage names in global markets.

- After‑sale maintenance becomes a feature, not a hassle—resole rather than replace.

The Craftsmanship Behind Every Pair

Precision in Every Step

- Cutting and pattern design

Great uppers start with precise patterning and careful clicking (cutting leather with grain and stretch in mind). That precision is what keeps the shoe symmetrical and supportive through thousands of steps. - Stitching mastery

Welt sewing and outsole stitching are the quiet heroes. The line must be neat, tension even, and placement perfect; it’s not only about strength—it’s a big part of the shoe’s visual language at the edge. Brands that obsess over this earn fans for life.

The Patina Hand-Coloring Process

Here’s where artistry meets customization. Hand patina finishing turns leather into a story—depth, gradation, subtle highs and lows, like light hitting aged wood. For small and mid-size private‑label brands, this is a signature move: a luxury aesthetic that looks bespoke and can’t be mass‑replicated by high-speed color spraying. Hengxin has spent years refining hand-coloring—now touting a third‑generation method that yields richer, more dimensional finishes.

Hengxin’s Manufacturing Edge

- True Goodyear welt capability in China

Beyond standard gemming, Hengxin states it uses a 360° channeling insole approach—carving a holdfast into a thicker insole and stitching the welt directly—combining bespoke‑style integrity with assembly‑line efficiency. They even claim to be the only factory running 360° channeling Goodyear welted construction on an assembly line, producing around 200 pairs daily. For brands, that’s the sweet spot: hand‑grade construction, reliable volume. - OEM & ODM flexibility

From initial sketches and last selection to prototypes and full-scale orders, Hengxin supports private‑label partners with design collaboration, fit guidance, and consistent QC. If you’re building a premium line, that soup‑to‑nuts support matters. - Integrated craftsmanship and modern efficiency

Traditional steps—lasting, welt sewing, cork filling, sole stitching—meet modern production planning and finishing discipline, which is how you hit timelines without compromising standards. If you’ve ever worried about scaling a Goodyear-welted program, that combination is your seatbelt.

Want to see the aesthetic in action? Explore Hengxin’s private‑label dress shoes or browse a clean single‑monk silhouette your customers will instantly “get.”

Why More Brands Choose Goodyear Welted Shoes for Their Product Lines

- Superior durability and comfort

That cork midlayer molds to the foot; the welted construction protects the upper during resoles. Over time, cost‑per‑wear plunges, satisfaction soars, and returns drop. As one English maker puts it, the welted method “enables complete removal of the sole without damaging the upper.” That’s the whole game for service life. - Brand prestige and value positioning

In the mind of the consumer, Goodyear welting signals “serious shoe.” It’s the construction associated with the Northampton tradition and many of the names you hear enthusiasts rave about. That halo can help emerging labels stand alongside heritage peers—if the execution is up to snuff. - Sustainability and longevity

Resoleable designs keep shoes in circulation for years and out of landfills. The Financial Times recently spotlighted how well-made welted shoes can be repaired repeatedly, with customers rejuvenating the same pair for decades. That’s not just an heirloom vibe; it’s a real sustainability story your customers can stand on. - Partnering with skilled manufacturers

Goodyear welting is as much choreography as it is construction. A reliable production partner—one who can execute a proper welt stitch, manage cork composition and shank placement, and finish soles cleanly—will make or break your line’s reputation. Hengxin’s model is designed to give you that precision plus transparency and speed.

A quick visual: how Goodyear welt compares

| Construction | How it’s built | Comfort & feel | Water resistance | Resoling | Typical look |

| Goodyear welt | Welt stitched to insole rib/holdfast and upper; outsole stitched to welt; cork fill | Supportive; molds over time | Better than Blake; welt acts as barrier | Designed for multiple resoles | Slightly wider sole edge; classic |

| Blake stitch | Single stitch runs through insole, upper, and outsole | Flexible, sleek, lightweight | Less resistant than Goodyear | Possible, requires specific machinery | Slim, close-cut edge |

| Cemented | Sole glued to upper, no welt stitch | Light and cushioned out of the box | Depends on materials; generally lower | Not designed for resoling | Varies; often modern profiles |

References on definitions and differences: see the Goodyear welt overview and Primer’s clear explainer on Blake and cement.

Real-life example you can share with your customers

“You might be wondering… will anyone actually resole these?” Absolutely. Repair programs and independent cobblers exist because a Goodyear-welted shoe invites it. As James Fox of Crockett & Jones put it, “We make around 100,000 pairs of Goodyear welted shoes at our factory every year,” a scale that goes hand‑in‑hand with long-term aftercare. Customers don’t just buy; they maintain. That’s a very different relationship than fast-fashion footwear.

A note on 360° channeling vs. standard gemming

Most factory Goodyear shoes use a canvas “rib” (gemming) glued to the insole; the welt stitch passes through that rib. Channeling, by contrast, carves a holdfast directly into a thicker leather insole—more like bespoke practice—so the welt stitches into leather rather than fabric. Hengxin’s claim is that they implement 360° channeling on an assembly line, marrying hand-grade technique with production throughput. For brands, that can mean a tighter build and a shoe that breaks in faster.

For manufacturers: practical takeaways you can brief your team on

- Specify the insole approach (gemming vs. channeling/holdfast) based on your brand’s positioning and target price.

- Lock in your last strategy early; fit and silhouette are the “face” customers recognize.

- Define your cork recipe and shank spec (comfort and support live here).

- Decide where patina belongs in your story—core styles, limited finishes, or seasonal capsules.

- Partner with a factory that can sample quickly, scale predictably, and hit QC standards every time. Hengxin’s private‑label process lays out each step, which makes planning smoother for your merch calendar.

Conclusion: Building Timeless Value from the Ground Up

Shoemaking has plenty of shortcuts. Goodyear welting isn’t one of them. It’s tradition meeting modern engineering: the welt as the quiet hero, the cork as your custom comfort layer, the resoling pathway as your sustainability plan. When your product roadmap includes shoes customers can wear for years—then repair and keep wearing—you’re not just selling footwear. You’re building trust.

And the partner matters. With deep experience in Goodyear welt construction, third-generation patina know-how, and production designed around OEM/ODM support, Hengxin stands out as a premier men’s shoe factory. We give brands a way to tell a richer story: quality, art, reliability—stitched together and ready to scale.

If you want a live example to show your team, start with these private-label dress shoes, then compare a refined single-monk in person. Seeing the edges, the stitch line, the finish—it clicks fast.

FAQ

Q: Why are Goodyear welted shoes considered premium?

A: Because of how they’re built: the welt-and-insole connection, the cork fill that molds to you, and the outsole stitched to the welt for easy resoling. It’s time‑consuming, requires skilled operators, and produces shoes designed for long service life.

Q: How does Goodyear welt compare to Blake stitch or cement construction?

A: Blake is sleek and flexible, with a single interior stitch through insole and outsole; it can be resoled with the right machinery but offers less water resistance. Cement is light and cost‑effective but generally not designed for resoling. Goodyear sits at the “serviceable, long‑term value” end of the spectrum.

Q: Are Goodyear welted shoes resoleable?

A: Yes—that’s the point. Because the outsole is attached to the welt (not the upper), a cobbler can snip the stitch and replace the sole without compromising the structure. Many makers highlight this as a core benefit.

Q: What materials work best with Goodyear welted construction?

A: Full‑grain calf and other premium leathers shine here, supported by a leather insole, cork fill, a steel or wooden shank, and a leather or rubber outsole. The welted method keeps these layers serviceable and stable.

Q: How long do Goodyear welted shoes typically last?

A: With rotation, basic care, and timely resoles, think years—often a decade or more. The serviceability is why enthusiasts and traditional makers love them (and why museums in Northampton still celebrate this craft).